Troubleshooting A Stuck Handwheel On A Singer Sewing Machine

Is the handwheel on your Singer sewing machine stuck and won’t turn? A jammed handwheel can be incredibly frustrating when you’re trying to complete a sewing project or make repairs. Luckily, with some troubleshooting, you can often get a stuck Singer handwheel turning again.

If you’re short on time, here’s a quick answer to your question: Try spraying lubricant into the handwheel mechanism, cleaning out any built up lint or thread, and making sure the belt isn’t too tight or slipped off. Gently wiggle the handwheel while applying pressure.

If it still won’t budge, the issue may require disassembling the machine.

Check for Obstructions in the Handwheel

When troubleshooting a stuck handwheel on a Singer Sewing Machine, one of the first things to check for is obstructions in the handwheel. This can occur when lint and thread buildup gets tangled around the mechanism, preventing it from moving smoothly.

Remove lint and thread buildup

A common cause of a stuck handwheel is a buildup of lint and thread in the machine. Over time, these materials can accumulate and clog the gears and moving parts, causing the handwheel to become jammed. To fix this issue, turn off the machine and unplug it from the power source.

Then, remove the needle plate and bobbin case to gain access to the inner workings of the machine. Use a small brush or tweezers to carefully remove any lint or thread that may be causing the obstruction. Once the debris is cleared, the handwheel should be able to move freely again.

Check bobbin area and feed dogs

In some cases, a stuck handwheel may be caused by a problem in the bobbin area or with the feed dogs. The feed dogs are the small, tooth-like mechanisms that move the fabric through the machine as you sew. If these are not functioning properly, it can cause the handwheel to become stuck.

Check the bobbin area for any loose threads or tangled thread that may be causing the issue. Additionally, make sure the feed dogs are clean and free from any debris. Cleaning and properly lubricating these parts can help the handwheel to move smoothly again.

Inspect belt tension and positioning

If the handwheel is still stuck after checking for obstructions, it may be necessary to inspect the belt tension and positioning. The belt is responsible for transferring power from the motor to the handwheel, allowing it to rotate.

If the belt is loose or out of alignment, it can cause the handwheel to become stuck. To fix this issue, refer to the sewing machine’s manual for instructions on how to adjust the belt tension or reposition it.

In some cases, it may be necessary to replace the belt altogether if it is worn or damaged.

By checking for obstructions in the handwheel, including removing lint and thread buildup, checking the bobbin area and feed dogs, and inspecting belt tension and positioning, you can troubleshoot and resolve the issue of a stuck handwheel on your Singer Sewing Machine.

Remember to always refer to your machine’s manual for specific instructions and consult a professional if you are unsure or uncomfortable performing any repairs yourself.

Lubricate the Handwheel Mechanism

One of the main reasons why a handwheel gets stuck on a Singer sewing machine is due to lack of lubrication. To ensure smooth operation of the handwheel, it is important to regularly lubricate the mechanism.

This will not only help prevent the handwheel from getting stuck, but also extend the lifespan of your sewing machine.

Use sewing machine oil or lubricant spray

When it comes to lubricating the handwheel mechanism, you have two options: sewing machine oil or lubricant spray. Sewing machine oil is specifically designed for use on sewing machines and is readily available at most sewing supply stores.

Lubricant spray, on the other hand, provides a convenient and mess-free way to lubricate the handwheel mechanism. Whichever option you choose, make sure to follow the manufacturer’s instructions for proper application.

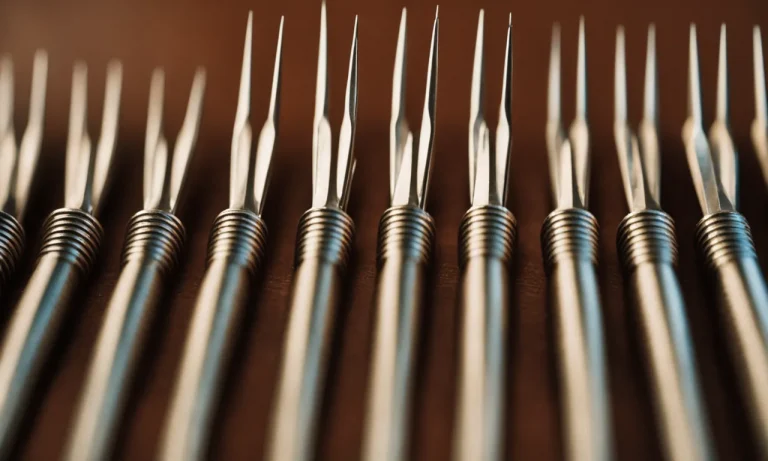

Focus lubrication on key friction points

When lubricating the handwheel mechanism, it is important to focus on the key friction points. These are the areas where the handwheel comes into contact with other parts of the machine. Apply a small amount of oil or lubricant to these areas, making sure to distribute it evenly.

This will reduce friction and allow the handwheel to move freely.

One common mistake people make when lubricating the handwheel mechanism is using too much oil or lubricant. This can actually attract dust and lint, leading to further issues with the handwheel. Remember, a little goes a long way.

If you’re unsure about where to apply the oil or lubricant, consult your sewing machine’s manual or visit the manufacturer’s website for guidance. Singer, for example, provides detailed instructions on how to lubricate their sewing machines on their official website (www.singer.com).

By regularly lubricating the handwheel mechanism, you can keep your Singer sewing machine running smoothly and avoid the frustration of a stuck handwheel. Remember, preventive maintenance is key to ensuring the longevity of your machine and enjoyable sewing experience.

Diagnose Issues with the Handwheel

When your Singer sewing machine’s handwheel gets stuck, it can be frustrating and hinder your sewing progress. However, with a little troubleshooting, you can identify the root cause of the issue and get your machine back in working order.

Here are some steps to help you diagnose issues with the handwheel:

Test handwheel for tightness and binding

The first step in troubleshooting a stuck handwheel is to check for tightness and binding. Start by gently turning the handwheel in both directions. If you feel resistance or hear any unusual noises, it could indicate that the handwheel is too tight or that there is something obstructing its movement.

In such cases, try loosening the handwheel by turning it counterclockwise. If the problem persists, you may need to inspect the gears, cams, and mechanisms.

Inspect gears, cams, and mechanisms

Issues with the handwheel can often be traced back to problems with gears, cams, or other mechanisms within the sewing machine. To inspect these components, you’ll need to remove the machine’s casing or access panel. Check for any signs of damage, such as broken teeth on gears or misaligned cams.

Additionally, look for any debris or thread that may be caught in the mechanisms, as this can cause the handwheel to become stuck. Remove any obstructions or clean the affected areas as necessary.

Assess damage or worn parts

If you’ve tested the handwheel for tightness and inspected the gears, cams, and mechanisms without finding a resolution, it’s possible that there may be damage or worn parts that need to be addressed.

Depending on the specific model of your Singer sewing machine, there may be replacement parts available for purchase. Consult the machine’s manual or contact Singer customer support for guidance on identifying and replacing damaged or worn parts.

Remember, if you’re unsure about any steps in troubleshooting your Singer sewing machine’s handwheel, it’s always a good idea to seek professional assistance. A certified technician can diagnose the issue accurately and provide the necessary repairs to get your machine running smoothly again.

Disassemble the Handwheel Assembly

Consult service manual for model-specific steps

Before disassembling the handwheel assembly on your Singer sewing machine, it is essential to consult the service manual that came with your specific model. Different models may have slight variations in their assembly, so it is crucial to follow the correct steps to avoid causing further damage.

The service manual will provide you with detailed instructions and diagrams specific to your machine, ensuring that you disassemble the handwheel correctly.

Document and label parts during disassembly

When disassembling the handwheel assembly, it is essential to document and label each part carefully. This will help you remember the correct order of reassembly and ensure that you don’t misplace any components.

Taking pictures or making notes of the disassembly process can be incredibly helpful when it comes time to put everything back together. By documenting and labeling the parts, you can proceed with confidence, knowing that you have a clear record of the disassembly process.

Clean components and inspect for damage

Once the handwheel assembly is disassembled, take the time to clean each component thoroughly. Use a soft cloth or brush to remove any dirt, dust, or debris that may have accumulated over time. Inspect each part carefully for any signs of damage or wear.

Look for cracks, breaks, or excessive wear on gears or other moving parts. If you notice any damage, it may be necessary to replace the affected component to ensure the proper functioning of the handwheel assembly.

Reassemble properly with lubrication

When reassembling the handwheel assembly, it is essential to do so correctly to avoid any further issues. Ensure that each part is placed in the correct order, referring back to your documentation and labels if needed.

Additionally, adding a small amount of lubrication to the moving parts can help ensure smooth operation. Use a sewing machine oil or lubricant recommended by the manufacturer and apply it sparingly to the gears and other relevant components.

This will help reduce friction and extend the lifespan of your sewing machine.

Conclusion

Persistence and methodical troubleshooting are key when dealing with a stuck handwheel on a Singer sewing machine. Start by clearing any debris in the handwheel mechanism, lubricating key points of friction, and testing for binding issues.

For stubborn cases not resolved with basic steps, be prepared to dive deeper by partially disassembling the handwheel components for inspection and repair. With some time and care, you can often get a stuck handwheel turning smoothly again.